CalfExpert

DER moderne Tränkeautomat mit individueller Kälberfütterung, Vollmilchsystem, intuitiver Steuerung des Graphikdisplays und vielen weiteren Features.

Arbeitsflexibilität gewinnen: Datenanalyse per App unterstützt professionelles Management.

Bessere Aufzuchtleistung dank Wiegung. Frühe Kontrolle und Alarmierung senken Tierarztkosten.

Natürliches Trinkverhalten: Gesunde Entwicklung durch viele individuelle Mahlzeiten.

Ein moderner Tränkeautomat für Kälber

Der CalfExpert ist ein Kälbertränkeautomat, der nach neuesten Ansprüchen in der Kälberfütterung entwickelt wurde. Modernste Fütterungstechnik sorgt dafür, dass die Milch für die Kälber immer frisch angemischt wird. Dabei ist es egal, ob Milchaustauscher oder pasteurisierte Vollmilch zum Einsatz kommen. Der CalfExpert bereitet die Milch automatisch und tierindividuell zu.

Während die Kälber 24/7 gefüttert werden, sind Sie als Betreuer vollkommen flexibel in Ihrer Arbeitseinteilung. So hebt der Tränkeautomat Ihr Management in der Kälberaufzucht auf ein neues Niveau.

Die intuitive Bedienung am Grafikdisplay und die Verbindung zur mobilen CalfGuide App erleichtern Ihnen und Ihrem Team die Tierkontrolle. Alle Informationen Ihrer Kälber, Statusberichte und Alarmmeldungen haben Sie in der App und direkt am Automaten immer im Blick.

Verschiedene Futterprogramme bilden die Grundlage einer erfolgreichen und leistungsorientierten Kälberaufzucht in der automatischen Kälberfütterung. Arbeitszeitersparnis und völlige Kontrolle inklusive!

Ein Gerät - viele Vorteile

Was kann der CalfExpert? Wie verbessert er das Kälberwohl und die Arbeitsbedingungen? Welches sind seine wichtigsten Funktionen? All das erfahren Sie hier auf den Punkt gebracht:

Tierindividuell Füttern

Viele Kälber mit frischer Mischung und angepasst an das einzelne Kalb zu füttern, ist eine große Herausforderung. Mit dem CalfExpert wird's zum Kinderspiel.

Immer frisch angemischt

Der Kälbertränkeautomat CalfExpert mischt die Milch für jedes Kalb frisch an. Eventuelle Milchreste werden warmgehalten und bei längeren Trinkpausen aus dem System gespült. Andere Tränkeautomaten arbeiten mit einem zentralen Milchvorrat. In der so bei 40 °C bevorrateten Milch verdoppeln sich die Keime alle 20 Minuten. Beim CalfExpert hingegen ist maximale Hygiene und tierindividuelle Fütterung garantiert.

Individuell angepasst

Der zentrale Milchvorrat hat einen weiteren entscheidenden Nachteil: Moderne Futterprogramme (z.B. die metabolische Programmierung) benötigen zu Beginn der Aufzucht eine höhere MAT-Konzentration (z.B. 160 g/l), um einen Leistungsimpuls zu geben. In der Abtränkphase ist allerdings eine geringere Milchpulverkonzentration notwendig (130 g/l). Diese tierindividuelle Fütterung ist nur umsetzbar, wenn für jedes Kalb individuell angemischt wird, wie beim CalfExpert!

QuickChange-Logik für mehr Leistung

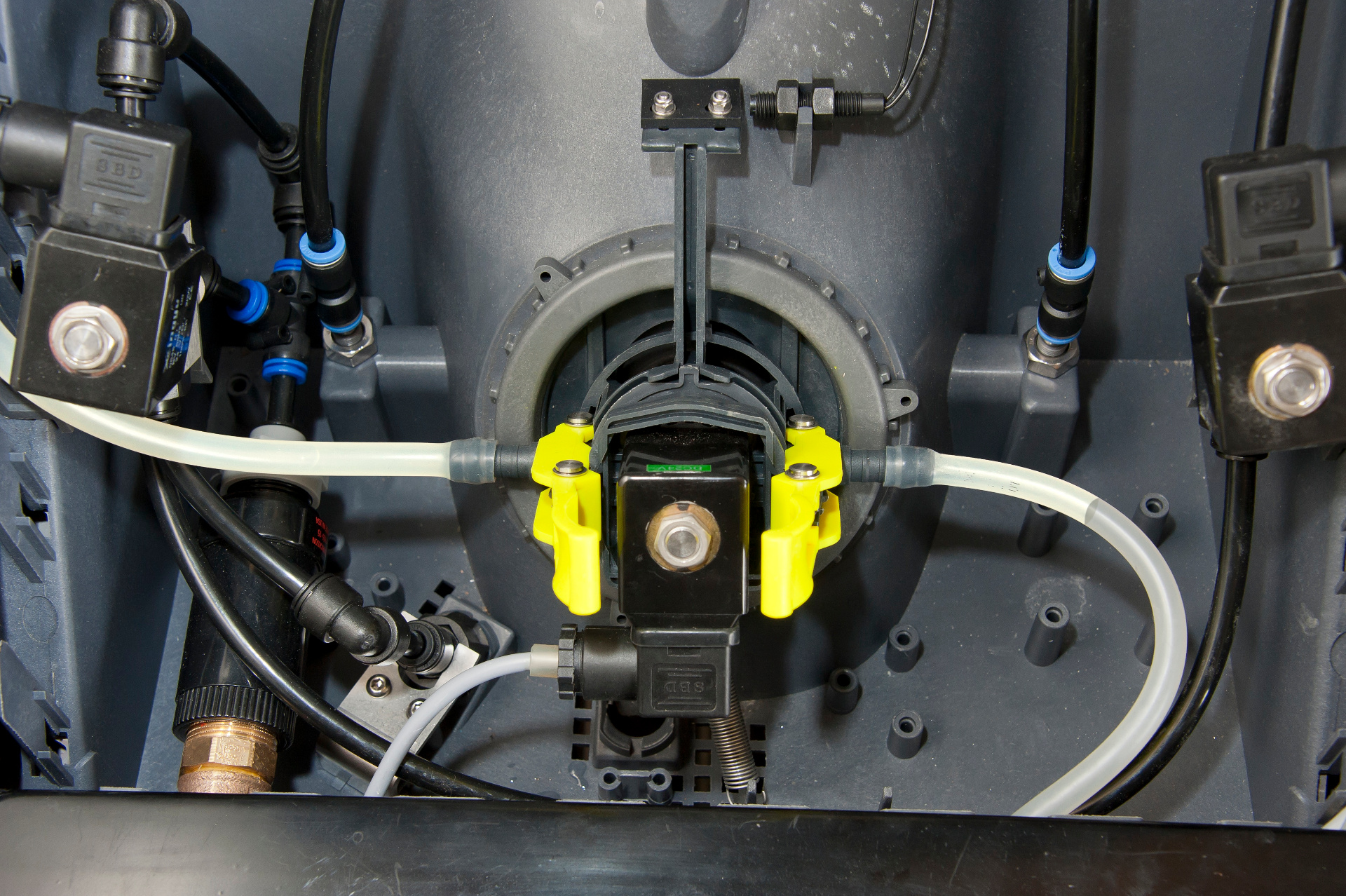

Beim CalfExpert haben wir den Anmischprozess und den Wechsel der Kälber beschleunigt und somit die Ausnutzung der HygieneStationen optimiert.

Die Milch wird schnell angemischt und ist schon nach 3 Sekunden an der Tränkestation abrufbar. Nach Beendigung der Milchmahlzeit wird umgehend auf die zweite Tränkestation gewechselt. Hier kann sofort ein zweites Kalb gefüttert werden, während das erste noch sein Saugbedürfnis stillt.

Zusätzlich können im Menü des CalfExpert Prioritäten festgelegt werden, sodass junge oder kranke Kälber bevorzugt werden. Das bewährte Gleitzeitprogramm sorgt dafür, dass die Mahlzeiten sehr gleichmäßig über den Tag verteilt werden, ohne dass es zu Besuchshäufungen an den Stationen kommt. Das Ergebnis sind reduzierte Wartezeiten bei hoher Tierbelegung und ein positives „Besuchserlebnis“ für die Kälber!

Ruhige und zutrauliche Kälber

Da es beim CalfExpert keine festen Futterzeiten gibt, können Ihre Kälber die Milch jederzeit abrufen. Sie werden nicht mehr als Amme gesehen, sodass die Kälber ruhig bleiben, wenn Personen den Kälberstall betreten. Jüngere und schwächere Kälber haben genügend Zeit, ihre Milch abzurufen.

Da der CalfExpert außerdem mit einer intelligenten Anrechtslogik arbeitet, haben alle Kälber zu einem anderen Zeitpunkt Tränkeanrecht. Das hat zur Folge, dass sich weniger Tiere an der Station drängen. Das Raubmilchventil verhindert den Milchraub durch stärkere Kälber. Das Ergebnis: Sehr gleichmäßige, entspannte Kälbergruppen!

QuadroFlex: Zeitgleich und doch flexibel tränken

Mit dem neuen QuadroFlex System können an zwei PowerMixern vier Kälber gleichzeitig trinken. Der CalfExpert rührt die Milch frisch an, wenn Kälber diese auch abrufen. Dabei kommt er ohne ein Vorratssystem aus. Die Tränkemenge wird für jedes Kalb über wartungsfreie Sensoren exakt erfasst. Wenn ein Kalb eine Sondermischung, z.B. Medikamente oder Elektrolyte, benötigt, wird nur die Schwesterstation am gleichen PowerMixer abgeschaltet. Am zweiten Power Mixer wird an beiden Stationen weiter gefüttert. So können 120 Kälber an 4 HygieneStationen gefüttert werden. Damit ist die Kapazität des CalfExpert im Vergleich zum Vorgänger H&L 100 um ca. 20 – 30 % erhöht.

Flexible Fütterungsprogramme

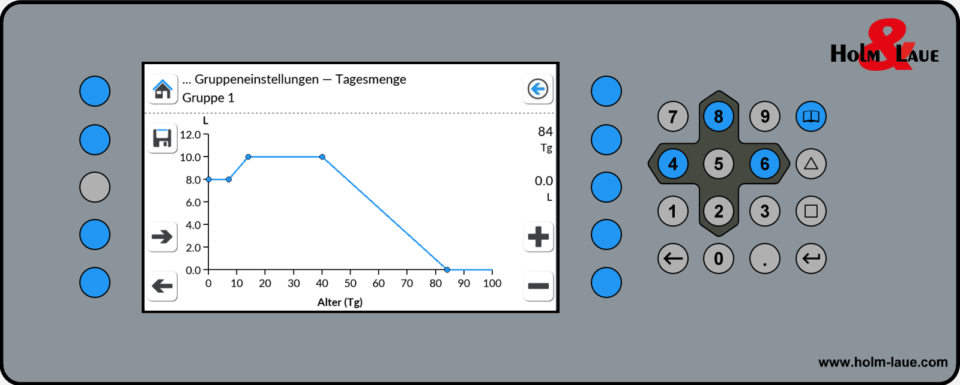

Moderne Fütterungsprogramme sollten sich immer an das Alter, die Rasse, das persönlich gesetzte Aufzuchtziel und den Gesundheitszustand der Kälber anpassen. All das können Sie am CalfExpert optimal umsetzen.

Abtränkverfahren

Der CalfExpert bereitet Ihre Kälber besonders schonend auf die Aufnahme von Kraft- und Raufutter vor. Er reduziert die Tränkemenge am Ende der Aufzucht in kleinen Schritten von 0,1 l pro Tag und stimuliert so die Entwicklung des Vormagensystems.

8 Futterkurven

Mit dem CalfExpert kann jedes Futterprogramm in die Realität umgesetzt werden. In jeder der 8 Gruppen können die Futterkurven sehr flexibel angepasst werden. Bis zu 16 „Wendepunkte“ erlauben Ihnen eine sehr feine Abstimmung Ihres ganz persönlichen Futterkonzeptes. Oder sie entscheiden sich für eines der bewährten und voreingestellten Futterprogramme im CalfExpert.

Metabolische Programmierung

Mit einer intensiven Fütterung in den ersten Lebenswochen ist später eine deutlich höhere Milchleistung zu erwarten. Allerdings stellt das richtige Abtränken der Kälber, zum Beispiel nach einer AdLibitumphase, jeden Kälberhalter vor besondere Herausforderungen. Am CalfExpert wird jedes Kalb langsam von einer hohen Milchaufnahme, sowohl in Volumen als auch in Konzentration, abgefüttert.

Milchpulver effektiv mischen

Flexibilität in der Fütterung bedeutet auch, dass verschiedenste MAT und Zusätze optimal und klumpenfrei zubereitet werden. Der stufenlos geregelte PowerMixer sorgt für ein sanftes Anlaufen, um Spritzer zu vermeiden und rührt das Milchpulver dann intensiv auf. So erhält das Kalb bereits nach 3 Sekunden seine frisch angemischte Milch direkt im Nuckel.

Bei jungen oder schwächeren Kälbern kann der Tränkevorgang schon mal länger dauern. Durch langsames Dauerrühren verhindern wir das Entmischen des Milchpulvers. Und wenn es kälter wird, sorgt die Heizung im Mixer immer für eine konstante Temperatur der Tränke, egal wie lange sich das Kalb Zeit lässt.

Zweiter Milchpulverraum

Mit dieser neuen Option können am CalfExpert zwei verschiedene Sorten Milchaustauscher (MAT) gefüttert werden.

Der Milchpulverraum steht im 90°-Winkel zum CalfExpert und fördert seitlich über eine Dosierschnecke Milchpulver in die PowerMixer des Automaten. Das Volumen von 50 kg MAT kann über die Pulverraumerweiterung um weitere 25 kg ergänzt werden. Auf diese Weise hat der CalfExpert mit einer maximalen Pulverlagerkapazität von 150 kg (2 x (50 + 25 kg)) den größten Milchpulvervorrat unter den Tränkeautomaten am Markt. Idealerweise geschieht das in einer Weise, dass eine Sorte Milchaustauscher die andere langsam ersetzt. Das kann z.B. sinnvoll sein, wenn in den ersten Lebenswochen ein hochwertiger Magermilchaustauscher zum Einsatz kommen soll, um die frühe Entwicklung der Kälber mit einer hohen Verdaulichkeit des MAT zu fördern. Später können dann günstigere Milchaustauscher genutzt werden, deren Inhaltstoffe (z.B. gewisse Anteile hochwertiger pflanzlicher Proteine) den Übergang zum Wiederkäuer unterstützen sollen.

Gezielt Zusätze füttern

Zur Stabilisierung des Verdauungstraktes können Sie Futterzusätze in kleinsten Mengen in die Milch dosieren. Kranke Kälber können mit Medikamenten in der Milch versorgt werden. Sie können zwei Pulverdosierer und zwei Flüssigdosierer einsetzen. Wie beim Milchprogramm, können Sie auch für diese Zusätze verschiedene Futterkurven programmieren. Das bedeutet maximale Flexibilität für beste Kälbergesundheit!

EvenMilk: Intelligente Vollmilchfütterung

Vollmilch wird vom Kalb ideal verdaut und führt zu höchsten Leistungen. Mit dem CalfExpert Vollmilchprogramm können Sie Vollmilchanteile oder eine Aufwertung der Vollmilch im Futterprogramm flexibel einstellen. Was passiert bei Ihrem Automaten, wenn der Vollmilchvorrat aufgebraucht ist? Füttert er dann mit Milchpulver? Das verursacht Umstellungsstress bei Ihren Kälbern und Verdauungsprobleme sind wahrscheinlich. „EvenMilk“, unsere intelligente Vollmilchsteuerung, weiß, wie viel Vollmilch vorhanden und wie viel zu füttern ist. Sie sorgt dafür, dass selbst bei täglich schwankenden Vollmilchmengen, Vollmilch und MAT in ausgeglichenen Anteilen angemischt werden.

Sauber und zuverlässig

Ein Tränkeautomat soll Ihre Arbeit erleichtern und kontinuierlich 24 Stunden seinen Dienst tun. Dafür muss er auch unter den rauen Bedingungen eines Kälberstalles zuverlässig arbeiten, so wie der CalfExpert.

Schlauchreinigung bis zum Nuckel

Früher zeigten einige Schlauchsysteme Ablagerungen von verkeimter Milch, da sie zu selten oder nicht vollständig gereinigt werden konnten. Die HygieneStation spült den gesamten Milchschlauch bis in den Nuckel während längerer Trinkpausen. Zusätzlich wird das komplette Milchsystem mehrmals täglich gereinigt. Wenn der Milchtank DoubleJug verwendet wird, wird auch die Zuleitung zum CalfExpert automatisch mit gereinigt. Das senkt die Keimbelastung für das Kalb, steigert die Kälbergesundheit und spart manuelle Reinigungsarbeiten.

Zwei Reinigungsmittel

Um die Reinigung noch weiter zu optimieren, kann der CalfExpert zwei verschiedene Reiniger einsetzen: Entweder zu jedem Reinigungszyklus abwechselnd oder in einem Reinigungsvorgang kombiniert (alkalisch, spülen, sauer, spülen). Die Reinigungsmittelpumpen sind außen angebracht. Somit können sie direkt aus den Behältern ansaugen. Das ist sicher und bequem. Zusätzlich generiert der CalfExpert automatische Meldungen, sobald ein Kanister leer ist.

Fliegenschutz serienmäßig

Zwei große Türen verschließen den sensiblen Anmischbereich. Dadurch können keine Fliegen in die Milch gelangen und Störungen des Milchsystems werden vermieden. Die Türen sind abschließbar, damit keine Verletzungsgefahr für Kinder besteht.

Integrierte Bedienungsanleitung

Im 7″-Grafikdisplay können nicht nur alle Kälberdaten bequem abgelesen werden. Über die Taste mit dem Buch, können in jeder Programmebene Hilfetexte und Informationen aus der Bedienungsanleitung abgerufen werden.

Einsatzbereit bei jedem Wetter

Kälber lieben das Außenklima, Ihr CalfExpert auch! Er verfügt über ein Frostschutzprogramm, das automatisch aktiviert wird, sobald Frostgefahr besteht. Sensoren in jeder HygieneStation und im Anmischraum des CalfExpert messen die Umgebungstemperatur und passen dann die Anmischtemperatur und die Intensität des Frostschutzprogrammes an. Sie können den Automaten problemlos von außen mit Wasser reinigen, denn alle sensiblen Bauteile sind gegen Spritzwasser abgedichtet.

Einfache Wartung

Die regelmäßige Kontrolle der Technik ist leicht: Im Wartungsmenü können Sie alle wichtigen Bauteile des CalfExpert schnell und einfach testen. Auch die Kalibrierung ist schnell selbst zu erledigen, denn die Software sagt Ihnen immer genau, was zu tun ist. Wir empfehlen Ihnen, den CalfExpert einmal jährlich vom spezialisierten Servicetechniker warten zu lassen. Das gibt Ihnen Sicherheit, dass der Automat zuverlässig in die neue Kälbersaison startet.

Automatische Kalibrierung

Der CalfExpert überprüft die Durchflussmenge von Milch und Wasser in regelmäßigen Abständen. So ist eine gleichbleibende Tränkemenge für die Kälber gewährleistet, ohne dass Sie sich aktiv darum kümmern müssen. Auch wenn das für die Pulvermenge leider nicht gilt, erinnert Sie der Automat, sobald eine Kalibrierung vorgenommen werden sollte. Mit der Option Brix-TS gleicht der CalfExpert allerdings Abweichungen in der Mischkonzentration aus, so dass Sie in jedem Fall sicher sind, dass die Kälber korrekt gefüttert wurden.

Smarter Arbeiten - Mehr Leistung

Zwei Fliegen mit einer Klappe: Mit dem CalfExpert werden Sie nicht nur von lästigen und anstrengenden Arbeiten befreit. Darüber hinaus wird durch intelligente Software und smarte Bedienung auch die Fütterungsqualität erhöht.

SmartKeys

Unter bewusstem Verzicht auf Touchtechnologie setzen wir auf die Nutzung von sogenannten SmartKeys: So kann der CalfExpert auch bei Frost, Regen, mit Handschuhen oder gar dreckigen Fingern zuverlässig bedient werden. Die leuchtenden SmartKeys zeigen Ihnen den Weg durch das Programm.

Die völlig neue Steuerungssoftware bietet maximale Übersichtlichkeit und einfache Bedienung des CalfExpert. Alle Kälberdaten mit individueller Futterkurve, Alarmlisten, technische Parameter u.v.m. sind im 7″-Grafikdisplay abrufbar. Über die WLAN-Verbindung können Sie einzelne Daten auch über mobile Endgeräte abrufen oder Push-Nachrichten bei Fehlermeldungen erhalten.

Mehr Einkommen durch bessere Leistung

Kälber, die mit viel Energie versorgt werden, starten früher in die Laktation und geben später mehr Milch! Mit dem CalfExpert haben Sie darüber hinaus die besten Voraussetzungen für optimale Tiergesundheit. Das bedeutet geringere Verluste und mehr Tiere in der Nachzucht des eigenen Betriebes. Das wiederum gibt Ihnen die Möglichkeit, den Nachwuchs gezielt zu selektieren und überschüssige Färsen gewinnbringend zu verkaufen. Und last but not least: Durch die Arbeitseinsparungen werden Kapazitäten auf Ihrem Betrieb frei, die Sie gewinnbringend nutzen können.

CalfGuide App

Der CalfExpert hat eine serienmäßige WLAN-Schnittstelle. Über die CalfGuide App können Sie wichtige Informationen direkt am Mobiltelefon abrufen. Das sind die allgemeinen Automatendaten und Details der Kälberlisten mit der gesamten Kälberhistorie. In der App können Sie Informationen der Kälber und auch Futterkurven bequem ändern. Weiterhin sendet der CalfExpert Nachrichten beispielsweise bei leeren Reinigungsbehältern. Besonders praktisch ist ein Gesundheits-Check, mit dem Sie den Gesundheitszustand Ihrer Kälber objektiv bewerten können.

AmmoniaDetect

Ammoniak reizt, auch in geringen Dosen, die Schleimhäute der Kälber. Das kann auf Dauer zu Bronchitis führen, die schnell zur Lungenentzündung wird. Ammoniak wird als Geruch erst dann wahrgenommen, wenn er schon im schädlichen Bereich ist. AmmoniaDetect ist ein elektrochemischer Sensor, der dauerhaft den Ammoniakgehalt in der Stallluft misst. Er wird, durch ein Rohr vor den Kälbern geschützt, direkt im Liegebereich angebracht. Der CalfExpert analysiert die Messwerte laufend und dokumentiert sie in einer grafischen Auswertung. So können Sie die Lüftung des Kälberstalls optimieren und den optimalen Zeitpunkt zum Ausmisten feststellen.

Zeit und Flexibilität gewinnen

Kümmern Sie sich um Ihre Kälber, wann SIE wollen und lassen Sie sich nicht von den Kälbern den Tag diktieren. Besonders morgens und abends fallen oft andere Arbeiten und Verpflichtungen an: das Melken und Füttern der Kühe, das Frühstück für die Familie vorbereiten oder die Kinder zur Schule bringen... Der CalfExpert füttert Ihre Kälber. Sie kontrollieren nur noch die Technik und die Tiere. Und das Anlernen reduziert sich mit der neuen HygieneStation auf ein Minimum.

Automatisierte Arbeitsabläufe

Mit dem CalfExpert weiß jeder Mitarbeiter, was er wann zu tun hat. Zu regelmäßigen Zeiten erledigen sie Kontrollarbeiten, Nuckelwechsel usw. Der CalfExpert erstellt rechtzeitig Leermeldungen für Vollmilch und Reinigungsmittel. Und um Hektik zu vermeiden, meldet der CalfExpert dies bereits einige Stunden, bevor die Behälter tatsächlich leer sind.

Ein Automat der mitwächst

Mit dem CalfExpert füttern Sie an 4 Stationen bis zu 100 Kälber, mit QuadroFlex sogar bis zu 120 Kälber! Wenn Sie heute noch weniger Tiere füttern, erlaubt Ihnen unser Baukastensystem später jederzeit die Erweiterung des Automaten mit allen angebotenen Optionen. So sparen Sie zuerst Geld und haben trotzdem später alle Möglichkeiten.

Ausstattung und Optionen

Grundausstattung CalfExpert

- 1 PowerMixer mit SoftStart-Logik und Heizung

- Frische, tierindividuelle Zubereitung der Milch

- CalfExpert Fütterungssoftware mit integrierter Bedienungsanleitung und Hilfefunktionen

- 7″-Graphikdisplay mit SmartKey Tastatur

- 8 Futterkurven voreingestellt (inkl. metabolischer Futterkurve)

- Nachspülen von Anmischbehälter und Saugleitung

- Zwei Spülmittelpumpen zur automatischen Reinigung aller milchführenden Teile mit automatischer Leermeldung

- Reinigungstemperatur bis zu 65 °C

- Leicht zu reinigende Edelstahl- und Kunststoffoberflächen

- Pulvervorrat für 50 kg MAT bei nur 112 cm Einfüllhöhe

- Starke Pulverschnecke für unterschiedliche MAT geeignet

- Automatische Registrierung neuer Kälber

- Keine stressigen Fütterungszeiten durch individuelles Gleitzeitprogramm

- QuickChange-Logik für schnelleren Anrechtswechsel zwischen den Kälbern

- Speicherkapazität für 250 Kälber

- Selbst aktivierendes Frostschutzprogramm

- Serienmäßiger Fliegenschutz

- Serienmäßiges WLAN im Automaten

- Gratis CalfGuide App: alle wichtigen Informationen auf dem Smartphone

- Automatische Kalibrierung der flüssigen Futtermittel

Zusatzausstattung CalfExpert

- Zweiter PowerMixer

- QuadroFlex (paralleles Trinken von 4 Kälbern)

- bis zu 4 Dosierer für feste und flüssige Zusätze

- Pulverraumerweiterung + 25 kg MAT

- Vollmilchsystem

- MilkBoy Lagertank

- DoubleJug Milchkühltank

- CalfGuide Managementsystem

- HygieneStation (optional inkl. Nuckelreinigung, Display, Tierwaage) (siehe Optionen HygieneStation)

- Alarmampel

- AmmoniaDetect

- Zweiter Milchpulverraum

Technische Daten CalfExpert

| Stromversorgung und Heizleistung | 400 V 16 A (6 kW) oder 230 V 16 A (3 kW) |

|---|---|

| Kapazität an 4 Stationen | bis zu 100 Kälber (u. U. bis zu 150 Kälber) |

| Identifikationssystem | Multireader HDX und FDX |

| Vorratsbehälter Milchpulver | 90 l / 50 kg |

| Pulvereinfüllhöhe | 112 cm |

| Boilervolumen | 12 l |

| Maße | 60 cm x 70 cm x 121 cm |

| Platzbedarf | 100 cm x 100 cm |

Der CalfExpert auf einen Blick

Der CalfExpert hilft mir, weil...

- ich gerne Daten zu meinen Tieren dokumentiere und auswerte.

- ich die Daten überall zur Verfügung habe und jederzeit den Status meiner Kälber abrufen kann.

- ich so die Tageszunahmen meiner Kälber bestmöglich optimieren kann.

- ich die Gesundheit meiner Kälber genau im Blick habe und so die Tierarztkosten reduzieren kann.

- ich die Fütterung meiner Kälber bestmöglich an das natürliche Saugverhalten anpassen kann.

- ich tierindividuell Zusatzfuttermittel wie Vollmilchaufwerter, Milchaustauscher oder spezielle Vitamine und Mineralstoffe zufüttern kann.

- ich die Kälber in kleinen Schritten möglichst schonend abtränken kann.

- die Portionen immer frisch angerührt werden und so auch im Sommer immer die optimale Qualität aufweisen.

- bei gesundheitlichen Problemen der Kälber die Portionen sofort angepasst werden und beispielsweise direkt Elektrolyte mit gefüttert werden können.

CalfExpert mit 4 Stationen

CalfExpert mit 4 Stationen